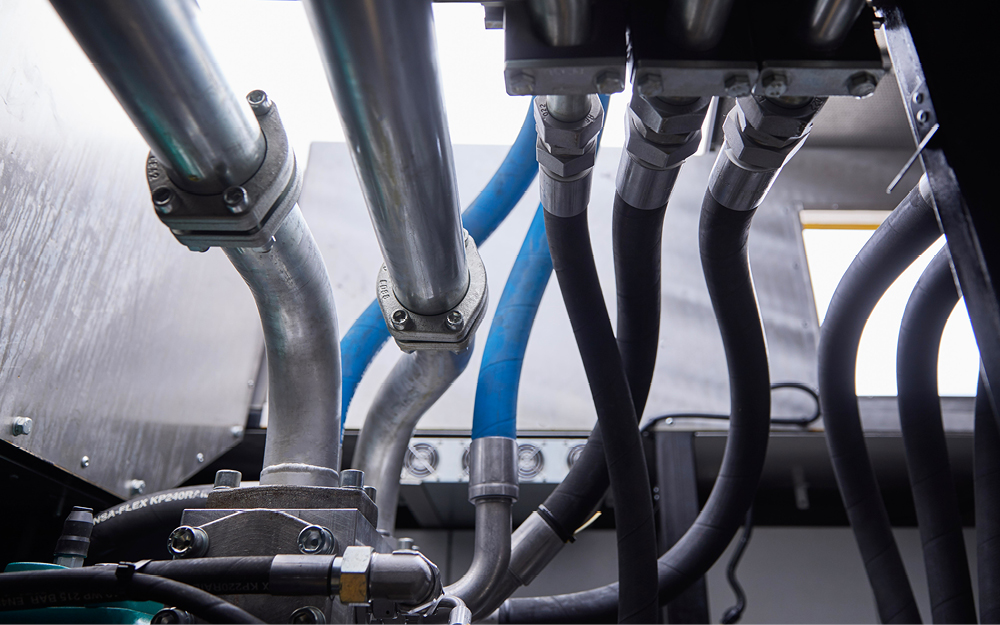

Preassembled hose lines, ready to install

We preassemble customised hydraulic hose lines from samples and to suit customer specific requirements for low, medium and high-pressure applications with the associated fittings in our branches. Our hose specialists always keep the safety of people and the environment in mind when selecting the materials and the method of joining the hose to the fitting. Whatever your need, we can advise you and manufacture a suitable hose line.

A system solution tailored to your requirements

The highest quality standards apply to our preassembled hose lines. The result is a leak-proof positive connection between hose and fitting, guaranteeing safety in use even at high pressures.

Advice and manufacture by experienced technicians

The preassembly and inspection of hydraulic hose lines are performed only by trained employees. They assemble suitable components for every proposed use and connect them properly together. Our technical employees as experienced contact partners see giving customer advice as part of their job and have undergone comprehensive training. In addition, officially authorised persons for whose technology inspect your machines and systems on site and assess whether and which hose lines need to be replaced. They also advise you on how to optimise your hose arrangements.

Professional preassembly in the HANSA‑FLEX branch

Each of our branches has its own hose workshop to ensure faultless manufacture of hydraulic hose lines. Here our experienced technicians cut, peel and crimp hose products to form ready-to-install hose lines. With access to top-class machines and innovative hose technology, such as hose rollers, cutters, peelers, crimpers, devices for cutting to length, projectile cleaning, test mandrels and pressure test benches, our technicians manufacture high-performance hose lines of various sizes in their workshops to consistently high quality standards.

Rapid help in an emergency

Our mobile emergency service is available to you 365 days a year all around the clock for when a machine or system breaks down due to a defective hose line. Our service technicians manufacture a suitable replacement hose line for you in their mobile workshop and install it.

Professional preassembly guaranteed

Preassembling customised hose lines starts with cutting the hydraulic hose to the required length, then crimping and marking and finally an optional pressure test.

Hoses preassembled in your locality

As a fluid technology specialist with many years’ experience, HANSA‑FLEX offers the highest degree of flexibility, safety, durability and cost efficiency in hose line manufacture directly in its local branches.

Experienced technicians

Every hose is assembled and inspected by qualified personnel

Comprehensive support

We discuss your requirements and any potential for optimisation before manufacturing the hose

Extensive warehouse stock

Extensive stocks of common fittings and hoses ensure rapid completion

Quick delivery

We start work on your requirements without delay. You receive the finished hose line soon after completion

More benefits for you

- Optimum hose preassembly processes, cutting, peeling and cleaning

- High-quality components from HANSA‑FLEX and renowned manufacturers

- Personal service from our technicians on site

- HANSA‑FLEX is your guarantee of professional preassembly

- The perfect combination of fitting and hose

Preassembly of numerous hose types

In addition to hydraulic hose lines, we also manufacture hose lines for numerous other fields of application such as the transport of hot or abrasive media or for use in the food industry.

Preassembly of combined hose-pipelines

In addition to hydraulic hose lines, HANSA‑FLEX also manufactures combined hose-pipelines for a wide range of fluid technology applications. The experienced specialists use their comprehensive knowledge to advise you on the appropriate design and give helpful tips about correct installation.

- Implementation of flexible line geometries

- Advice for planning of hydraulic systems and machines

- High-quality processing using certified welding procedures

Preassembly of metal hose lines

We preassemble robust metal hose lines from high-quality corrugated hoses. Welding in accordance with DIN EN ISO 3834-2 guarantees a safe connection even under extreme conditions.

- Certified jointing processes, 100 % tested for leaks

- Nominal diameters from DN 6 to DN 250 mm

- Free of oil, grease and LABS, depending on requirements

Preassembly of industrial hose lines

In the specialist hose centre, we manufacture top-performing industrial hose lines to the customer’s wishes for the whole spectrum from construction to the chemical and food industries.

- Manufactured in accordance with the Pressure Equipment Directive, DGUV and T 002

- Preassembly including accessories and connection systems

- Suction and delivery hose line manufacture

Service with added value

Opting for HANSA‑FLEX hose preassembly also benefits you with a range of additional services.

Hose-related services

As well as manufacturing hose lines in series production facilities, we also offer various solutions for manufacturing customised, preassembled solutions for you directly on site. In addition, our experienced fluid experts can advise you with hydraulic li

- Series production

- Plant-in-plant production

- Workshop containers

- Installation of pipe and hose line syste

- Training courses

- Item 1

Hose line series production

Find out moreAs an experienced manufacturer of high-quality hose lines, HANSA‑FLEX manufactures ready-to-install hydraulic, high-pressure, PTFE and industrial hose lines in large or small batches for OEM suppliers. You can expect excellent process reliability and compliance with quality standards. We also adapt our procedures in warehouse product management and logistics to suit your requirements.

- Item 1

Plant-in-plant production for process efficiency

Find out moreWith plant-in-plant-production from HANSA‑FLEX, you benefit by having hydraulic hoses and other components manufactured in harmony with your in-house processes.

- The necessary components are made available Just-In-Sequence

- Any required unforeseen adaptations are quickly made on the spot

- Immediate availability of components, no warehousing costs

- Item 1

Customised hose lines made wherever you like

Find out moreThe HANSA‑FLEX hydraulics container is a mobile workshop with all the machines, tools and components required to preassemble hose lines in remote regions of the world.

- Maximum availability of hydraulic hose lines

- Minimising of time and money lost due to standstills

- Stocking, advice and training included

- Item 1

Pipe and hose installation for complete plants

Find out moreOur service technicians and installation teams install all the pipes and hoses on machines, systems or mobile hydraulic units. To do this they first identify the potential for optimisation, taking into account positions, dimensions, design, material choice and efficiency. The next step is to agree a time window for the work with you and then implement the required measures.

- Item 1

Expert knowledge of theory and practice

Find out moreIn conjunction with the International Hydraulics Academy, we offer a wide range of seminars and training in various fields of fluid technology, covering everything from the basics of hydraulics to the details of more complex topics.

- Knowledge of pneumatics, electro-hydraulics and proportional hydraulics

- Courses to become an officially authorised person for hydraulic line equipment

- Advanced training to become qualified as a hydraulics specialist (HWK)

These topics may also be of interest to you

Hoses and hose lines

The HANSA‑FLEX range includes hoses for hydraulics and pneumatics as well as for the transport of chemicals, food, air, water and abrasive…

Find out moreHose fittings

The fittings designed and manufactured by HANSA‑FLEX are perfect for use with the appropriate hose type. They guarantee a safe and leak-free…

Find out morePipelines

The HANSA‑FLEX range of pipeline products includes expansion joints, bent pipes and special fittings for liquids, gases and coolant water. HANSA‑FLEX’s state-of-the-art manufacturing…

Find out more