Switches and sensors for hydraulics

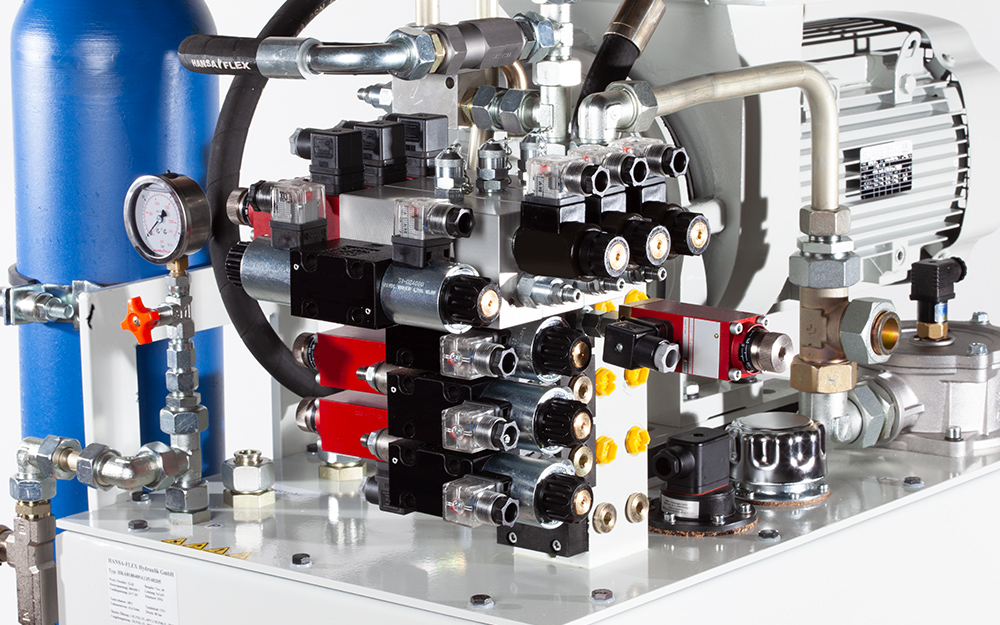

Switches and sensors for various process parameters, such as pressure, filling level and temperature, are used to regulate, control and monitor hydraulic systems. HANSA‑FLEX is a one-stop partner supplying a large selection of durable pressure, temperature and level switches and sensors. In addition, our experts advise you on the selection of the most suitable solution and support you in the optimisation of your machines and systems.

Switches and sensors for pressure, temperature and level control

The HANSA‑FLEX portfolio includes robust, analogue hydraulic switches and state-of-the-art sensors for interlinking hydraulic systems with electronic controls for all industries and applications.

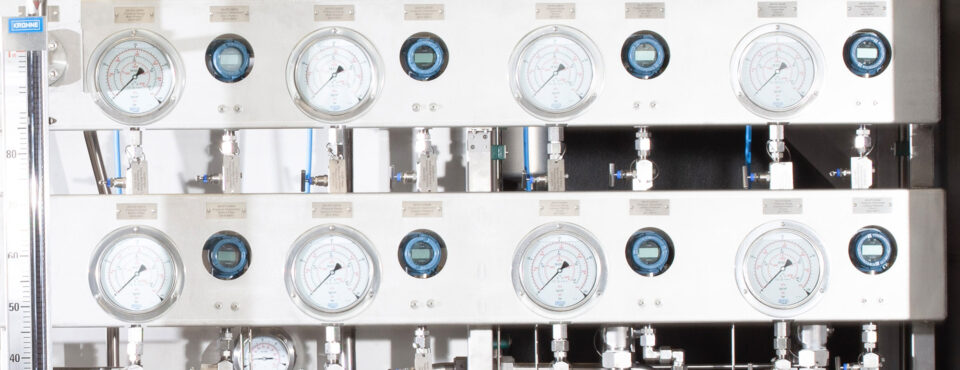

Analogue and digital pressure switches and sensors

Our online shop has a huge choice of mechanical pressure switches and electronic pressure sensors for automated monitoring and control of pressure levels in hydraulic systems.

- Mechanical pressure switches for pressure ranges of 5 to 630 bar

- Electronic pressure sensors optionally supplied with digital displays

- Compact unit comprising pressure switch and pressure sensor with LED display

Precision temperature switches with various switching points

Having the correct oil temperature is crucial to the proper functioning of a hydraulic system. Temperature switches allow you to reliably monitor the temperature of your hydraulic oil.

- For installation in pipelines or hydraulic tanks

- Various dip pipe lengths

- Switch hysteresis 10 Kelvin (+/- 5 Kelvin)

Compact level and temperature switches

Combined level and temperature switches from HANSA‑FLEX provide a very simple way to control the filling level and temperature of hydraulic fluids.

- Plastic or aluminium housing

- Programmable variants with LED displays optionally available

- Switch hysteresis: +/- 1 % of full scale value

Analogue and digital switches and sensors from hansa‑flex

Comprehensive product portfolio

Analogue and digital switches for monitoring pressure, temperature and filling level.

High availability

Well-stocked warehouses ensure short delivery times for your required components.

Customised configuration

Switches and sensors can be supplied with various connections to suit your specific requirements.

Our mission is to satisfy your requirements

Have you not found the right solution for your application in our online shop? In addition to the products listed there, we also have access to numerous other switches, sensors and stroke measuring systems for cylinders available elsewhere on the market. Give us a call! We will find the best solution for you.

Advice and support from experts

- Advice

- Servicing

- Optimisation

- Item 1

Comprehensive advice

The fluid experts from HANSA‑FLEX are always happy to answer questions about switch and sensor technology and provide comprehensive technical advice on the following subjects:

- Choice and optimisation of design

- Installation in hydraulic systems and controls

- Efficient operation and regular servicing

- Item 1

Servicing of hydraulic components, machines and sy

With our comprehensive know-how and extensive product portfolio in all areas of hydraulics, we can undertake all the servicing of your machines and systems in accordance with your requirements. This can relieve your employees’ workload and reduce preventative maintenance standstills.

- Completion of one-off and recurring servicing tasks

- Performed by experienced and trained service technicians

- Quick and straightforward replacement of components

- Item 1

Optimisation of machines and systems

As a system partner, we provide extensive support to you with all aspects of optimisation and modernisation of your machines and systems, with the aim of increasing efficiency and operational reliability.

- Continuous condition monitoring

- Effective fault analysis and competent fault rectification

- Identification of further potential for improvement

Good to know

What you should consider when selecting, installing and operating sensors and switches in hydraulic systems.

Redundancy in the equipment of systems

Faults or failures can occur in any electronic system. For this reason, it is sensible in certain cases to fit more than one switch in a hydraulic system. With redundancy built into the design of the control electronics, your system is reliably protected against switching faults should a switch fail. In addition, the fact that two measurements are taken gives a second value for comparison purposes. This also allows a failing switch to be detected. Safety can be further increased by adding an additional, purely visual display.

Choosing the right sensor

The choice of sensors depends on the installation situation, medium properties and ambient conditions. The application also determines the requirements in accordance with the relevant standards with respect to temperature resistance, IP type and shock and vibration load strength. You should consider the following when selecting your sensor:

- Measurement accuracy, measurement range, measured quantity and output signal strength

- Electrical and hydraulic connections

- Integration into machine and system controls

Prevent wear

Like all other system components, sensors are not 100 % protected from wear. However, you can considerably extend the service life of sensors by following a few simple rules:

- Do not exceed the specified measuring ranges.

- Do not use sensors in media for which they were not designed.

- Ensure the materials they are made from are suitable for the conditions of use.

- Operate the sensors with the correct electrical connections and parameters.

- Avoid overtemperature, shock and vibrations.

These topics may also be of interest to you

Measuring technology

Measuring technology in hydraulic systems must be highly precise. Pressure, temperature and volumetric flow need to be measured accurately to…

Find out moreDrive and control technology

Hydraulic components fulfil the highest quality standards at HANSA‑FLEX, where quality management has DIN ISO 9001 certification. Availability is ensured by…

Find out moreHydraulic unit manufacture

Hydraulic power units are the driving force at the heart of many hydraulic systems. Their components include a motor to…

Find out more