Doka simplifies construction with in-situ concrete with innovative formwork solutions

12.03.2024

Up among the clouds

What do the world’s highest building, bridges at a breathtaking height, long tunnels and massive power stations have in common? The answer is innovative formwork technology from Doka. With a workforce of over 6,000 in more than 70 countries the Doka Group is a global leader in the development, manufacture and sale of formwork technology. For smooth operations on construction sites in Germany Doka takes advantage of the dense branch network of its hydraulics partner.

The Nuttlar viaduct in the Sauerland region is an impressive bridge: at 115 m it’s the highest viaduct in the state of North Rhine Westphalia and, with a length of 660 m, it represents an essential section of the A46 motorway. Four of the six piers of the bridge were constructed with self-climbing technology from Doka. In this process it isn’t necessary for the formwork to be lifted by crane after every concreting stage – instead it climbs upwards autonomously with hydraulic support. The construction of the carriageway slab was also implemented with an innovative solution from Doka: hydraulically operated formwork carriages laid the foundations for rapid construction operations from below.

Moving ahead fast with construction

Change of location. The new European Central Bank building is now an established part of the Frankfurt skyline. At 185 m the skyscraper, which was ready for occupation in 2015, is Germany’s seventh-tallest building. The design by the Vienna architects Coop Himmelb(l)au imposed the highest demands on building technology: parts of the core and facades of the polygon-shaped double high-rise building are at different angles, with the layout of every ceiling varying. Formwork technology from Doka made a major contribution to fast construction operations – the shell grew by one storey every one or two weeks – by enabling the concreting of the ceilings in a way which was just as fast as it was simple.

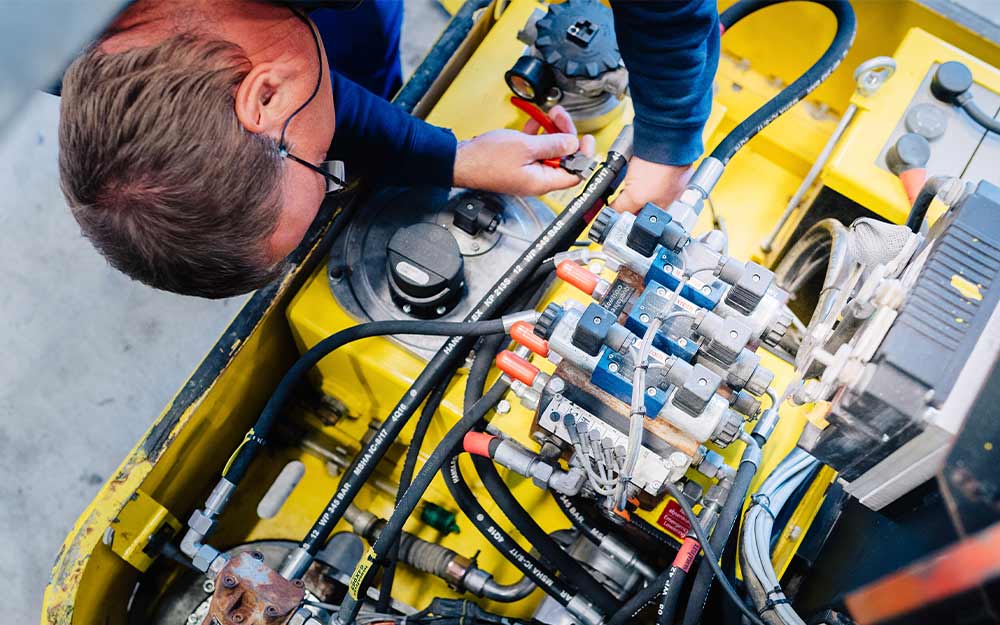

For this purpose Doka provides so-called ‘formwork tables’, which can be flexibly combined. In the past several persons were required for the horizontal repositioning of these formwork tables, but Doka has developed an ingenious solution for this in the form of its DoKarts. “This highly manoeuvrable mobile equipment enables both the transport and the raising and lowering of the ceiling tables by a single worker,” reports Ralf Jancke, Branch Logistics Manager at Deutsche Doka Schalungstechnik GmbH. Hydraulics is responsible for the high load-bearing capacity of up to 2 tonnes, with a battery-operated hydraulic pump generating the required pressure in the hydraulic cylinder. The high speed of lift also enables a faster working pace: ceiling tables of up to 12.5 m² in size can be raised at 8.5 cm per second.

“We work on the construction sites with up to 700 bar pressure. We can’t and don’t want to make any compromises when it comes to hydraulic hoses.

Ralf Jancke

Head of Branch Logistics Doka

On the spot without delay

The Doka service teams are regularly on-site at major construction locations such as the Nuttlar viaduct. They support the formwork specialists and carry out rapid repairs to formwork equipment and DoKarts. Wherever necessary maintenance work is carried out directly on site, in order to avoid expensive downtime. However, with such a wide variety of formwork technology it isn’t possible to keep spare parts in stock for all machinery and systems. This also applies to the hydraulic equipment, which plays a major part in Doka’s operations. “It would take too long to order spare parts which we don’t have in stock from our HQ in Austria. We therefore looked for an efficient hydraulics partner in Germany”, says Jancke. The major factor in the decision to cooperate with HANSA‑FLEX was the company’s comprehensive branch network, which guarantees short distances to the construction sites wherever they are. Further decisive factors were fast delivery times and reliable quality: “On our construction sites we work with pressures of up to 700 bar. That means we can’t accept any compromises when it comes to hydraulic hose lines”, he adds.

Clearly identified

Even though many hose lines look the same from the outside, there are fundamental differences: “For example, if hose lines designed for low pressure are used in high-pressure operations, accidents are inevitable”, explains Mario Thiel from the HANSA‑FLEX branch in Erfurt. Doka relies on the X-CODE system in order to avoid mixups. HANSA‑FLEX enters all the features of a hose line in a database, from which they can be accessed at any time using the code which is applied to the line.

As a result the X-CODE not only creates greater safety but also speeds up the process of obtaining the right spare parts: “From the construction site I simply call the nearest HANSA‑FLEX branch and all I need to provide them with is the six-digit X-CODE. When I then get to the branch my hose line is ready and waiting for me – exactly the way it should be. For the customer this is a valuable service”, confirms Jancke.

Always ready to help

Doka operates on construction sites throughout Germany: “Every project is different, every construction site has its own special features. What makes our work fascinating is the daily challenge of finding and delivering the perfect solution,” declares Jancke. And no matter how varied the construction projects themselves are, one thing always remains the same: the high quality standards which have made Doka a global market leader in the formwork industry. Accordingly, for Jancke and his colleagues in the maintenance section it is a major benefit to have a partner at their side on whom they can rely to the full. Summing up he states: “We have come to know many different HANSA‑FLEX branches. They all provide the quality and service we’re looking for. Even when we arrive with a complex enquiry, the staff there are always ready to listen and come up with a solution”.

Learn more

- 12.03.2024

The world’s most powerful industrial blower

Aerzener Maschinenfabrik produces the most powerful positive displacement blower in the world currently. Power units from Willmann ensure smooth operation of the blowers - even under explosive ambient conditions.Find out more - 12.03.2024

Harvesting the wind

With more than 26 years of experience in the development of wind turbines, Nordex SE is one of the major players in its field.Find out more